Acoustic guitar bodies are made out of extremely thin wood, usually between .080″ and .125″ thick. This thin wood has nowhere near the amount of strength required to hold up against the constant string tension and pressure. This is why the inside of an acoustic guitar has braces running across the top and back. Some acoustic guitars even have small braces on the sides of the body. These braces help reinforce the guitar body as well as transfer the tone.

To understand bracing, you must understand a little about how an acoustic guitar works. Acoustic guitar bracing is traditionally made out of lighter weight woods like Sitka Spruce. Light woods are usually desirable because they don’t dampen the vibrations of the guitar body. When the strings are played, they vibrate the bridge, which transfers energy to the top of the guitar. Any thing that is glued to the top of the guitar will deaden the vibrations, thus lighter braces are more favorable. Think about it like this. The heavier the braces are, the more difficult it is for the strings to vibrate the top of the guitar. There are many different schools of thought as to how to carve and tune guitar braces. I will reserve that topic for another article. In this article, I just want to talk a little about guitar brace construction and a few of the traditional guitar brace patterns.

Guitar Brace Construction

Contents

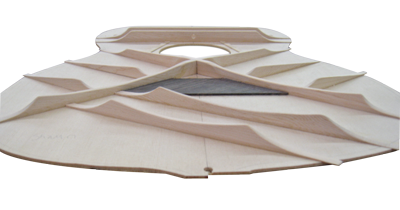

As I mentioned earlier, acoustic guitar braces walk the fine line between providing much needed support and actually hurting the tone of the instrument. Acoustic guitar braces are designed to be as lightweight as possible. Pretty much all guitar brace patterns incorporate scalloped braces light the picture to the left. These braces have a carved or scooped out center to reduce weight and allow maximum tone transfer while providing support for the guitar body.

The braces are also tucked under the kerfing of the body and butted against the bridge plate. When the strings are plucked, the bridge plate vibrates causing the braces to vibrate. These vibrations carry all the way down the braces and into the kerfing and guitar sides. It is all connected! So you can see how important it is to have braces that don’t weight down the guitar body.

Bracing Patterns

There have been many different bracing patterns throughout the years. More recently asymmetric acoustic guitar body designs have become popular causing builders to rethink and redesign the traditional brace patterns. With all of these modern changes to the guitar design, one design continues to be the most popular for it’s tonal quality and structural integrity.

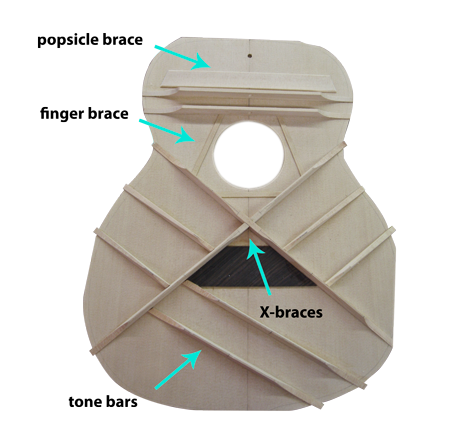

X-bracing

X-bracing or the X brace pattern has been around since the 1800s. We don’t really know who invented it, but it most commonly attributed to Christian Frederick Martin of the Martin Guitar Company between 1840 and 1845. The originally X-brace design was invented to support the first steel string guitars. Before the 1800s, acoustic guitars only had classical stings often made from animal guts. These guitars were incapable of producing and projecting loud sounds, so Martin sought out to fix that. With the industrial revolution well underway, Martin had, for the first time in history, steel guitar stings at his disposal. He could use these steel strings to produce a louder guitar. The only problem was that he had to create a guitar body capable of supporting the increased tension from the steel strings–thus the X-brace was born.

The X-brace consists of two braces crossing under the sound hole and either side of the bridge forming an “X” pattern. These two braces provide the majority of the guitar top’s support. Under the X-braces, there are typically two tone bars that help carry the vibrations from the X to the lower portion of the guitar top. Finger braces are usually placed around the sound hole. There is also usually a wide thin brace that is placed perpendicularly under the tongue of the fretboard for support. This brace is often called a popsicle brace.

Ladder Bracing

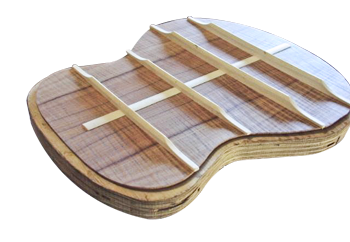

X-Bracing is only done on the top of the guitar because the guitar top receives the brunt of the string tension. The back also needs to be reinforced however. On steel string guitars one form of braces is most common: the ladder brace. Just like the X-brace, it gets its name for obvious reasons.

A ladder bracing pattern usually consists of one thin, wide brace running the joint of the back of the guitar back with three to four cross braces running from bass to treble side. Usually ladder braces are not scalloped.

Fan and Lattice Bracing

Both fan and lattice bracing patterns are found on classical guitars. These two patterns are not built for the extreme tension of a steel string guitar. They are designed to transfer tone and as much volume as possible for a classical guitar. A fan pattern resembles the shape of fan. These braces usually fan outward from the bridge plate pointing at the bout of the guitar almost like a cartoon drawing of sunrays. Lattice bracing, on the other hand, is an intricate placement of braces to form almost a checkered pattern.

These are just a few examples of the many different styles of guitar bracing. As the design of the modern guitar changes, so will the bracing patterns used to support it.